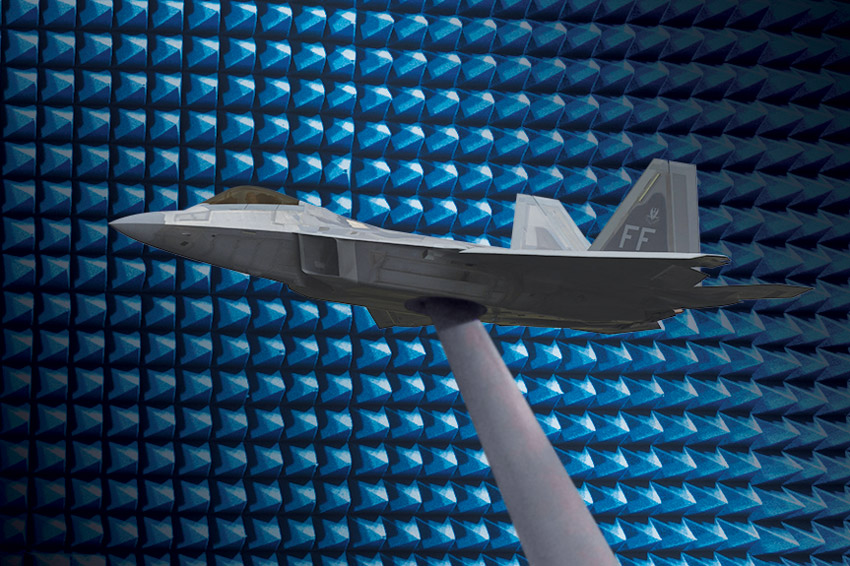

RCS Positioning Systems

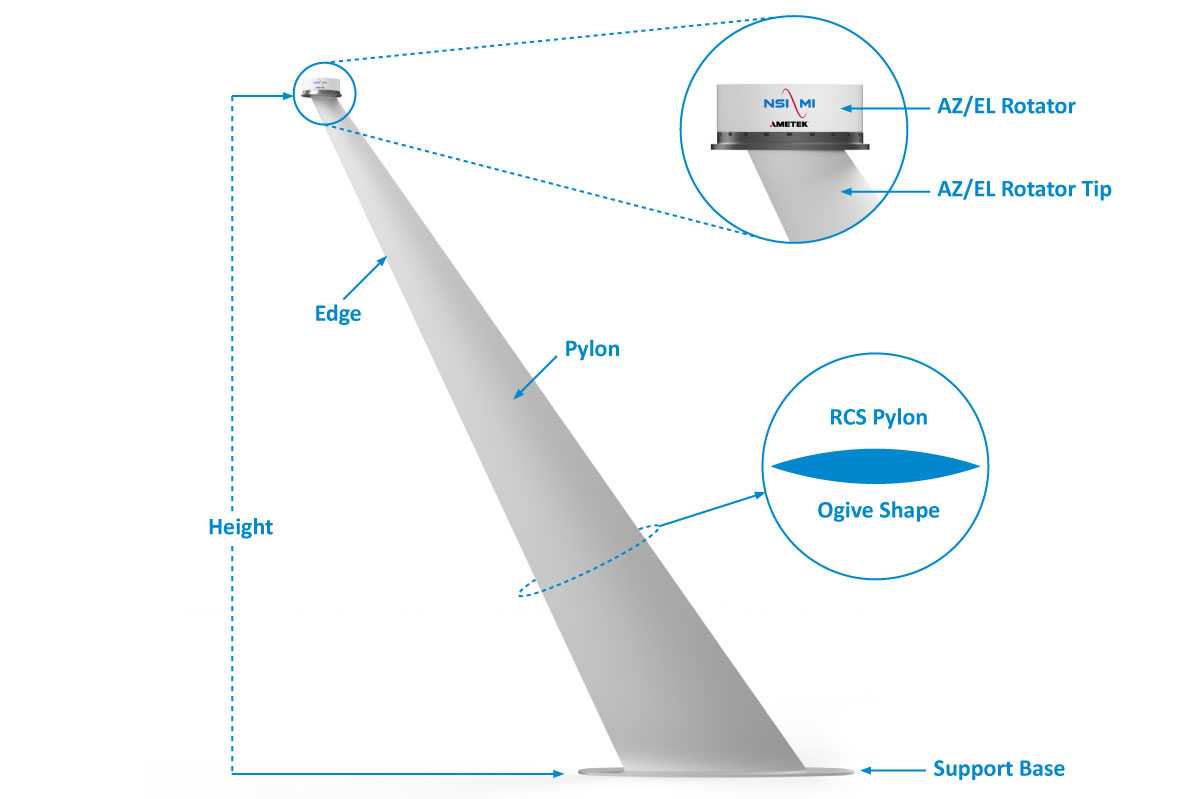

NSI-MI's Radar Cross Section (RCS) target positioning solutions are high-performance systems designed for conducting accurate and precise monostatic scattering measurements. These systems, consisting of a low-observable support structure (pylon) and azimuth-over-elevation rotators, offer exceptional edge sharpness and surface accuracy. Built with compact high-strength structures, high-power mechanical drives, low-backlash gearing, and high-accuracy absolute encoders, all models of the RCS target positioning system deliver outstanding performance. Using advanced features and customizable options, NSI-MI target positioning solutions provide the reliability and precision required for RCS measurements in a wide range of applications.

Features

- Structural rigidity for high repeatability

- Ogive available in 4:1, 6:1 and 7:1 ratios

- Interchangeable AZ/EL tip rotators

- Low angular backlash

- High performance in small envelope size

- Position control compatible with industry standard instrumentation radars

Datasheet

-

RCS Rotators

-

RCS Pylons

-

Standard Components

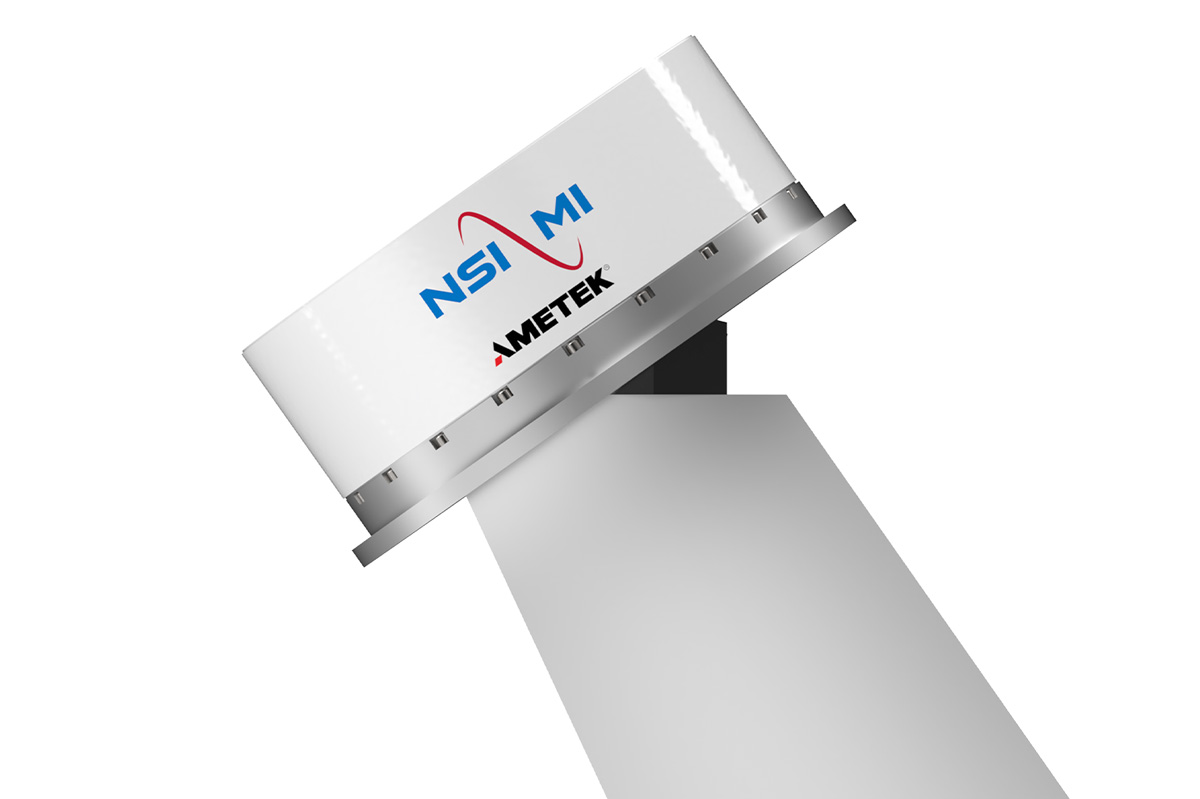

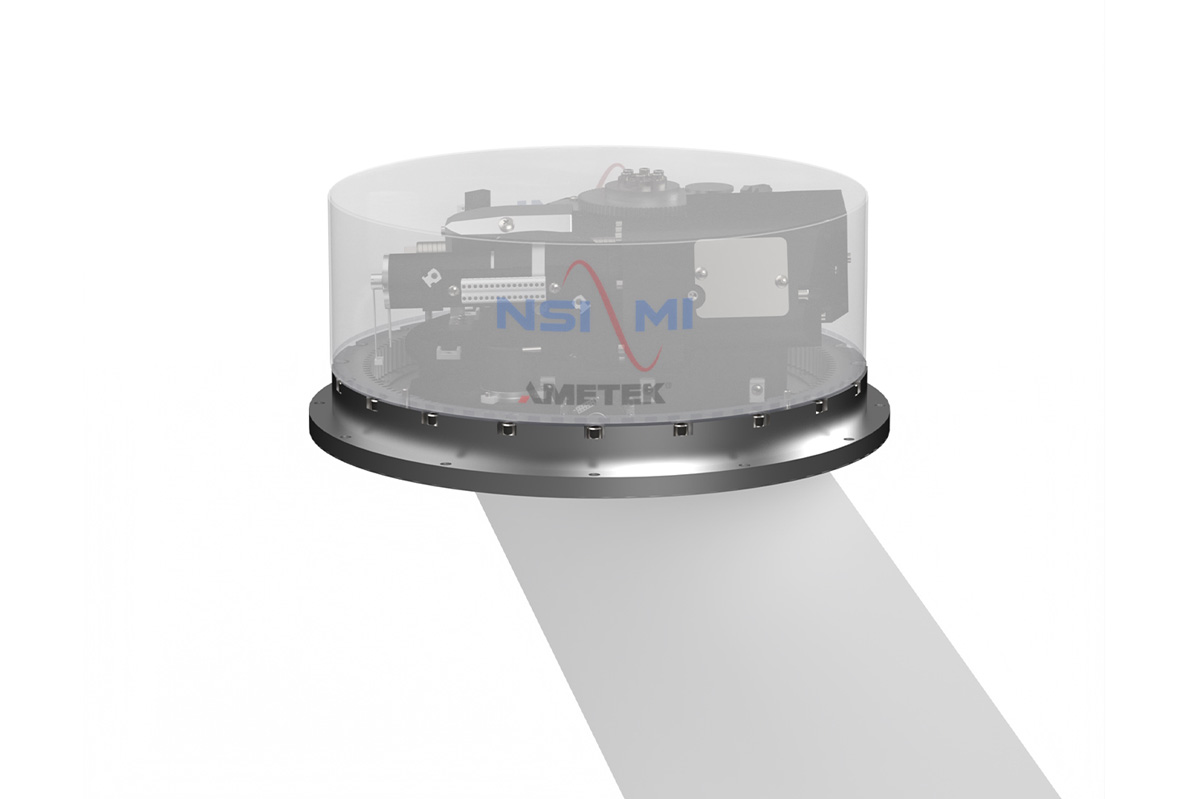

The RCS Rotator is a highly engineered positioner that offers extreme torque density in a compact size. It is designed to be used with RCS pylons for supporting targets during testing. The low-profile design allows the rotator to be contained within a test article to ensure the measurement remains unaffected by the positioner. Configured as azimuth-over-elevation two-axis positioners, NSI-MI’s RCS rotators offer a wide range of motion. The elevation axis typically has a range of -45 degrees to +5 degrees, with approximately one degree of overtravel at each end. The azimuth range of motion is continuous, providing flexibility in positioning. Multiple interchangeable RCS rotators and their associated tips are available to accommodate a wide range of cavity sizes and capacities. The elevation encoder is directly coupled to the elevation axis, ensuring accurate measurements. The azimuth encoder features antibacklash gearing, effectively eliminating bidirectional hysteresis. The RCS rotators also feature incremental encoders integrated into the brushless motors, providing precise velocity feedback for enhanced control of both axes. With its advanced features and compact design, the NSI-MI RCS rotator is a reliable and efficient tool for RCS measurement.

Features

- Structural rigidity for high repeatability

- Ogive available in 4:1, 6:1 and 7:1 ratios

- Interchangeable AZ/EL tip rotators

- Low angular backlash

- High performance in small envelope size

- Position control compatible with industry standard instrumentation radars

Light Duty

| Load Capacity | up to 1,814 kg (4,000 lb) |

|---|---|

| Delivered Torque, Azimuth | up to 407 Nm (300 ft-lb) |

| Delivered Torque, Elevation | up to 4,067 Nm (3,000 ft-lb) |

| Maximum Speed, Azimuth | 36.0–42.0°/min |

| Maximum Speed, Elevation | 3.0–6.5°/min |

| Backlash, Azimuth | 0.05° |

| Backlash, Elevation | 0.05° |

| Maximum Weak Axis Bending Moment, Operation | up to 2,034 Nm (1,500 ft-lb) |

| Position Readout Accuracy, Azimuth | ±0.05° |

| Position Readout Accuracy, Elevation | ±0.05° |

| Limit-to-Limit Travel, Azimuth | Continuous |

| Limit-to-Limit Travel, Elevation | +5 to -45 |

Heavy Duty

| Load Capacity | up to 22,676 kg (50,000 lb) |

|---|---|

| Delivered Torque, Azimuth | up to 42,072 Nm (31,031 ft-lb) |

| Delivered Torque, Elevation | up to 416,993 Nm (307,558 ft-lb) |

| Maximum Speed, Azimuth | 36.0–55.0°/min |

| Maximum Speed, Elevation | 5.0–12°/min |

| Backlash, Azimuth | 0.05°–0.06° |

| Backlash, Elevation | 0.05°–0.06° |

| Maximum Weak Axis Bending Moment, Operation | up to 96,308 Nm (71,033 ft-lb) |

| Position Readout Accuracy, Azimuth | up to ±0.03° |

| Position Readout Accuracy, Elevation | ±0.05° |

| Limit-to-Limit Travel, Azimuth | Continuous |

| Limit-to-Limit Travel, Elevation | up to +6 to -35 |

The NSI-MI RCS Pylons are rigid structures designed for RCS measurements, offering a solution with minimal backscatter. Constructed with highstrength steel or aluminum, this monocoque welded structure provides maximum structural rigidity while keeping the weight to a minimum. The customizable design allows for easy adaptation to meet specific load, deflection, low observability, and height requirements. Each RCS Pylon undergoes thorough inspection during the manufacturing process, including a proof load test and final inspection, ensuring the highest quality and performance. They are delivered with an edge protection kit, lifting fixture, and transport dollies. Whether used in military, aerospace, or research applications, the RCS Pylon offers a reliable and efficient solution for accurate RCS measurements.

Features

- Low backscatter

- High strength monocoque structure

- All weather design

- Excellent edge sharpness, surface accuracy and surface finish

- MEC-RTR RCS Rotator

- MEC-PYL RCS Pylon

- Edge protection kit

- Lifting fixture

- Transport dollies

.svg?la=en&revision=cee9767f-8e72-4d76-a07a-14ba25688269&hash=ADF64722447408F8CA70B4436F59CB64)