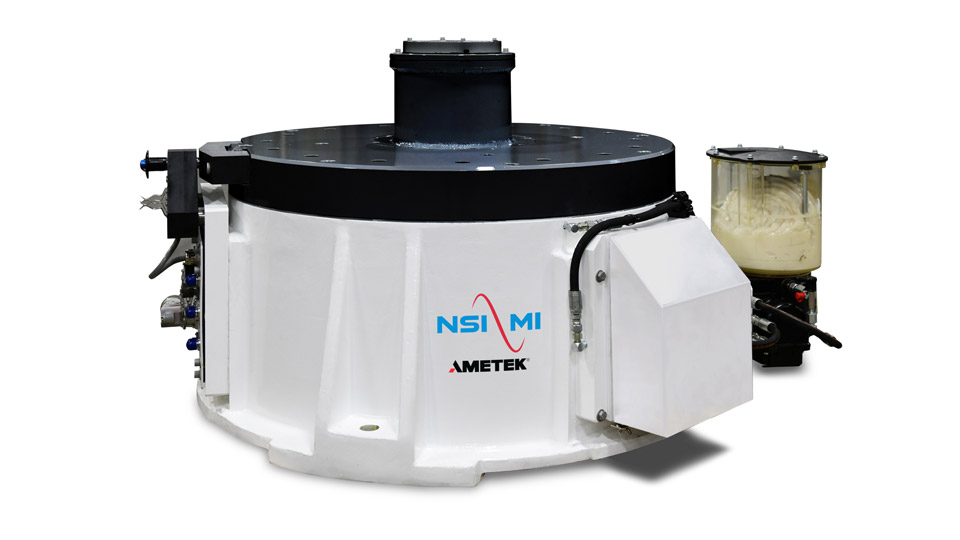

High Power Rotators

Model: MEC-HPR

Features

- Bending moments greater than 3,000,000 Nm (2,210,000 ft-lb)

- Payloads greater than 50,000 kg (110,200 lb)

- Speed up to 120 deg/sec (20 rpm)

- Standard and customizable configurations

- Delivers an unmatched combination of high-speed & high-torque

- Designed to meet military and federal standards for outdoor use in extreme weather conditions

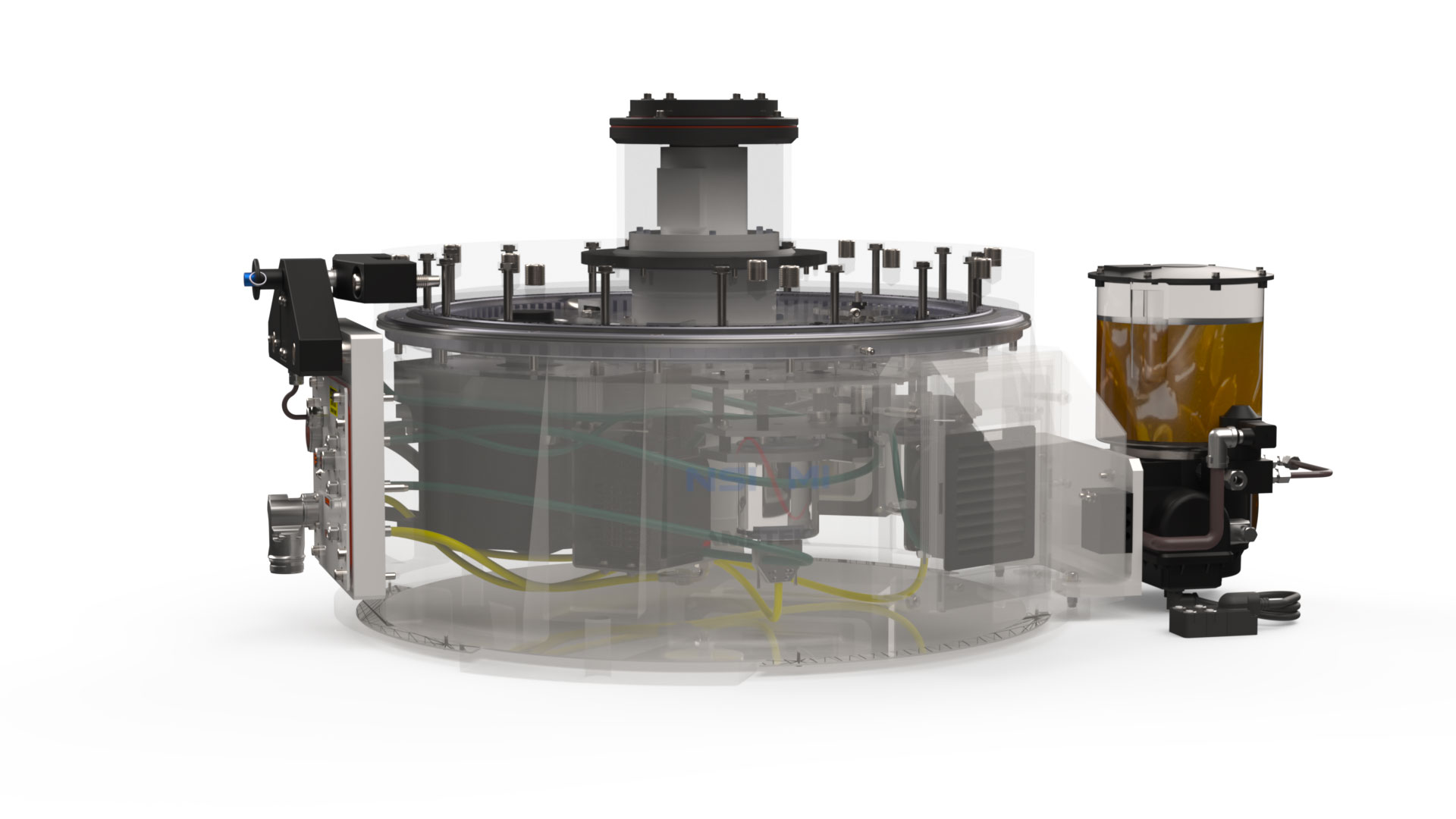

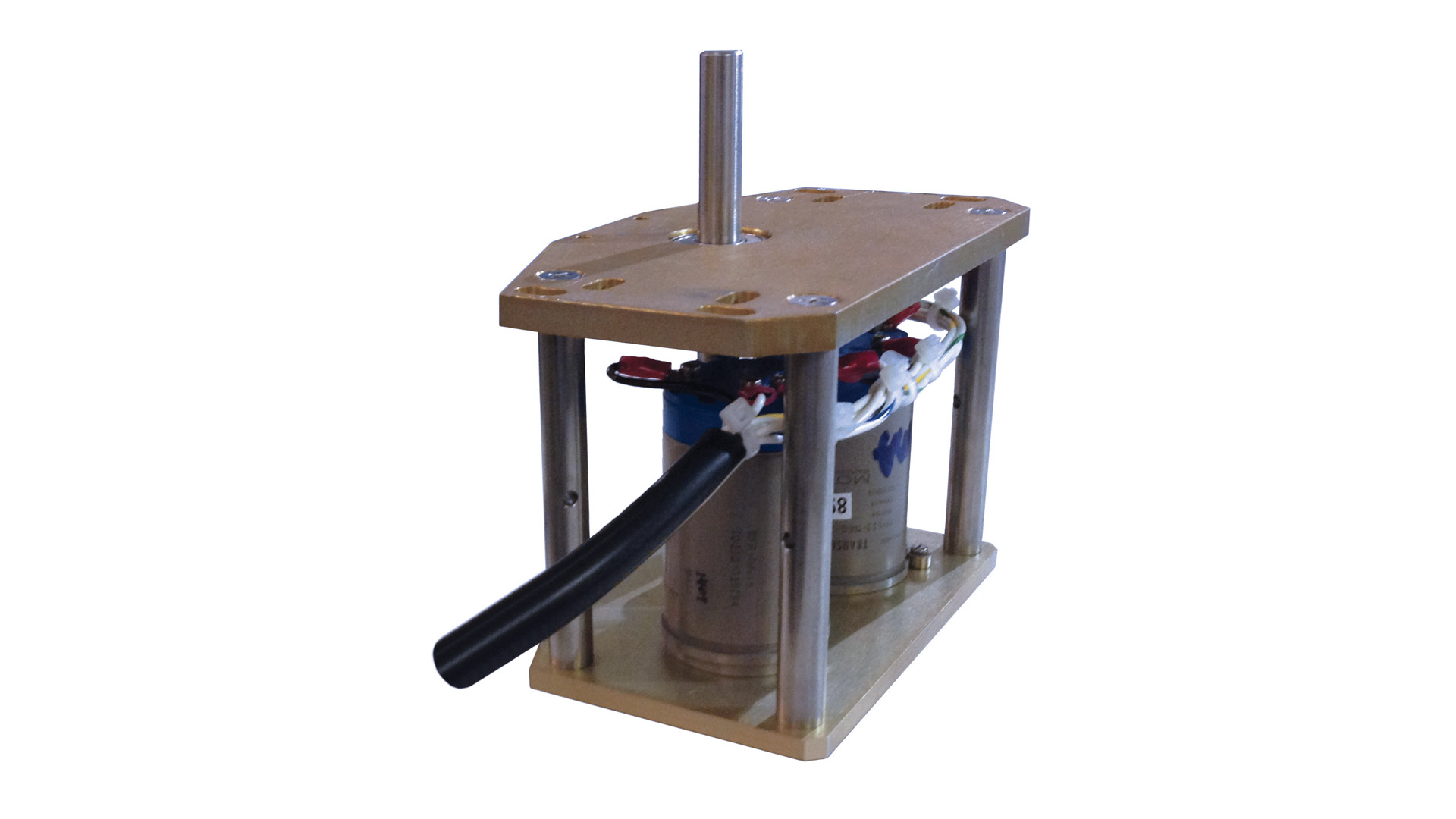

What are High Power Rotators?

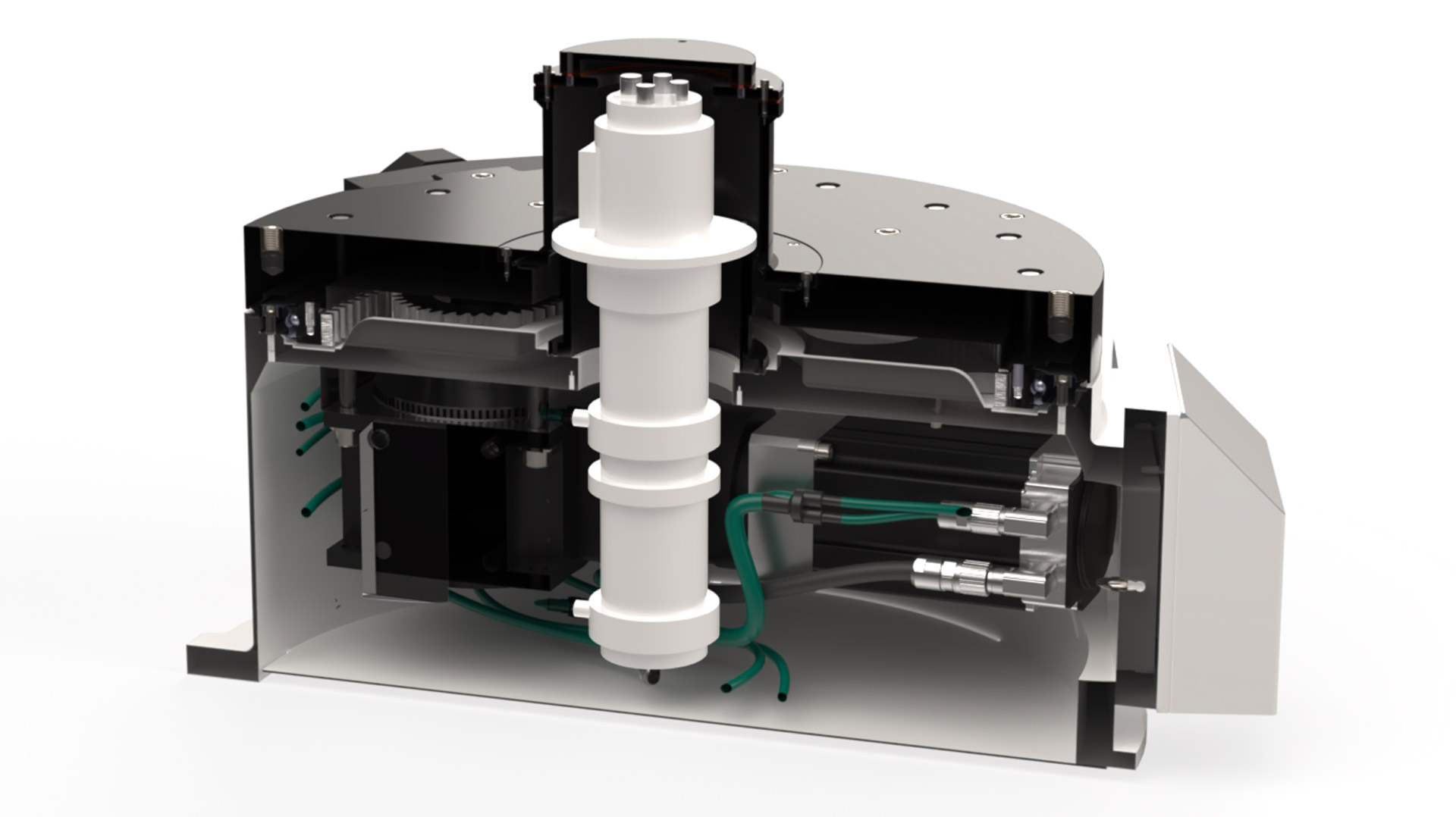

NSI-MI Technologies' High Power Rotators are built to handle heavy loads, high speeds, and endure harsh outdoor environments. They feature high structural and drive safety factors and are equipped with EMI gaskets to minimize electromagnetic interference, making them suitable for high RF power applications. Standard features such as stow pins, temperature control, customizable colors, and an automatic lubrication system ensure reliable performance for critical operations. The large thru-hole accommodates rotary unions, slip rings, rotary joints, and fiber optics, to allow for continuous, uninterrupted rotation. Each rotator comes equipped with an API-enabled position controller.

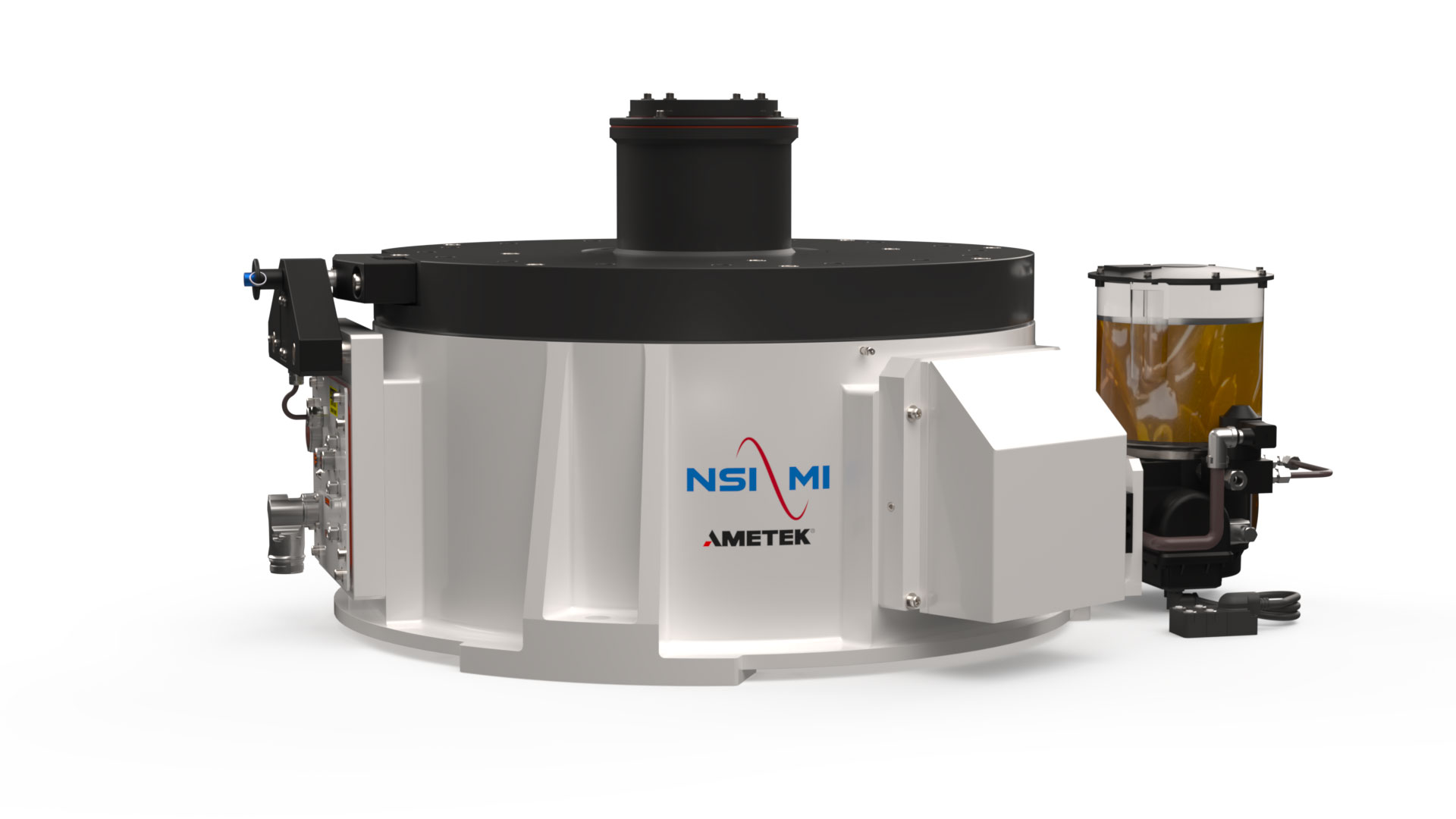

Built for harsh environments

NSI-MI High Power Rotators are specially designed for lasting performance in extreme operating conditions. All rotators support very wide temperature ranges and up to 100% humidity, making them ideal for outdoor environments. The optional temperature control system includes a heater module equipped with a built-in thermostat and fan to heat the internal volume of the rotator when ambient temperatures drop below freezing. Additionally, a thermostatically controlled fan evacuates warm air from the positioner if the internal temperature exceeds a programmable threshold. The optional lubrication system ensures that the system will remain operational in remote locations for mission critical applications. Some models have been designed with support for up to 95 km/h (60 mph) wind speeds for high altitude sites. Finally, MEC-HPR can be delivered in custom colors to maximize safety and discretion for outdoor applications.

|

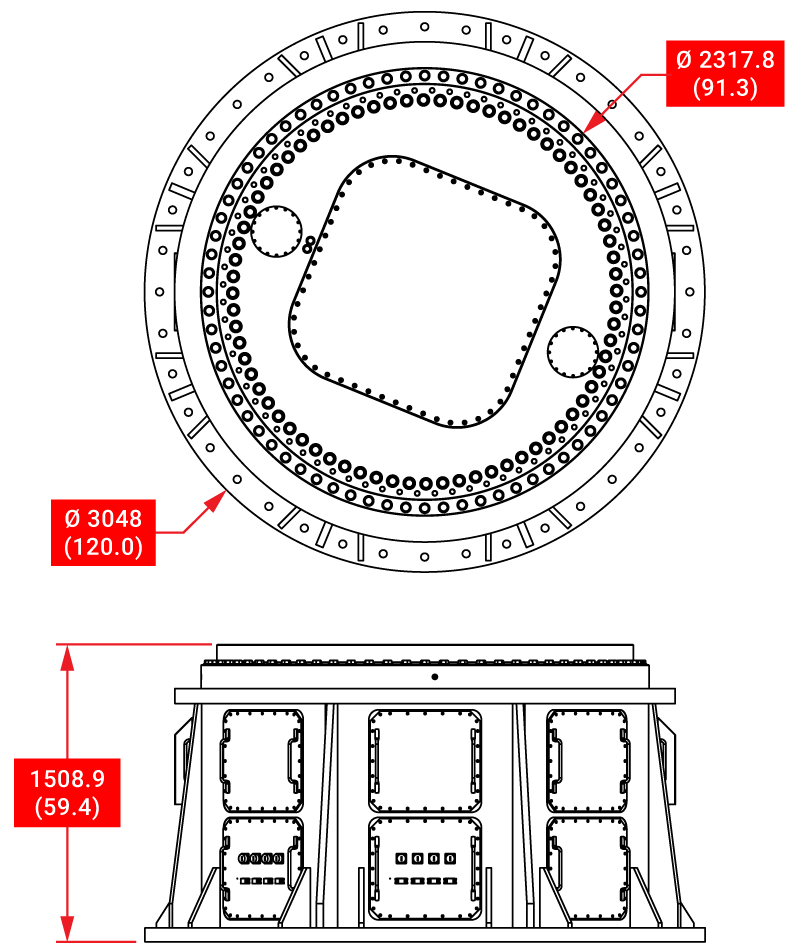

MEC-HPR Positioner Dimensions

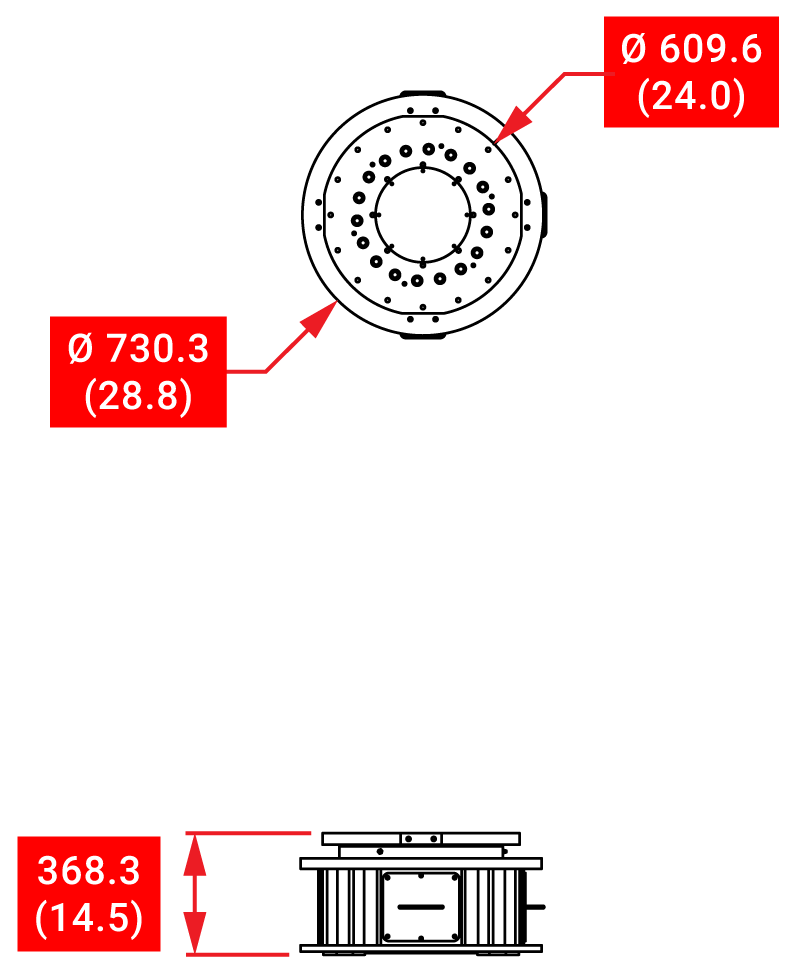

MEC-HPR-45

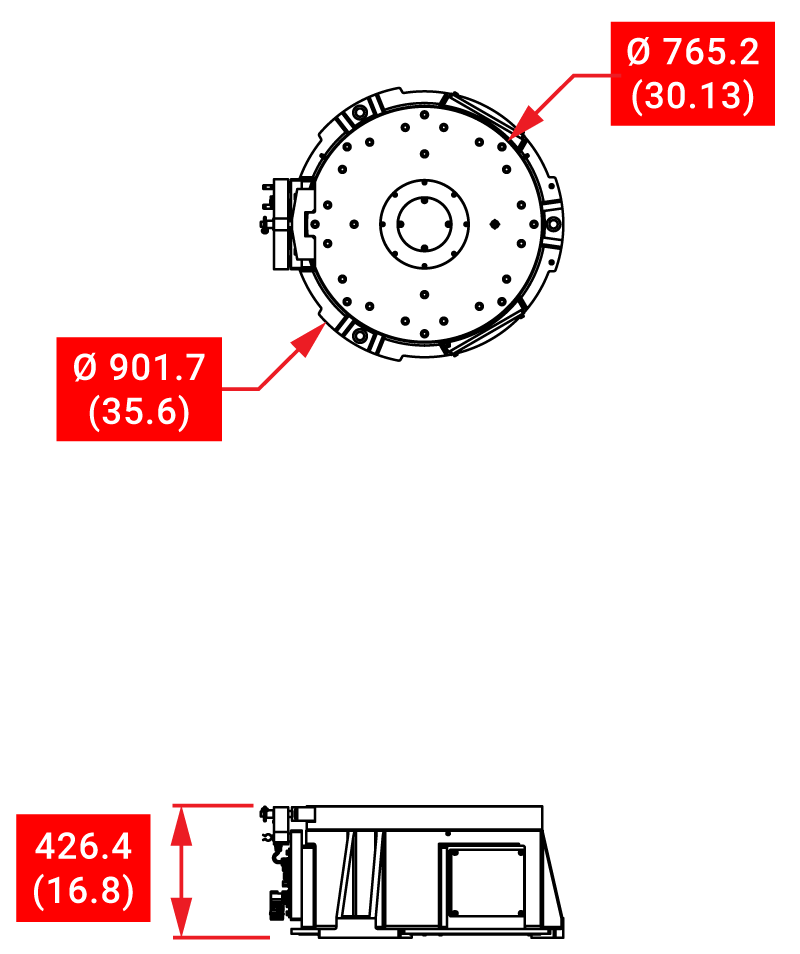

MEC-HPR-55

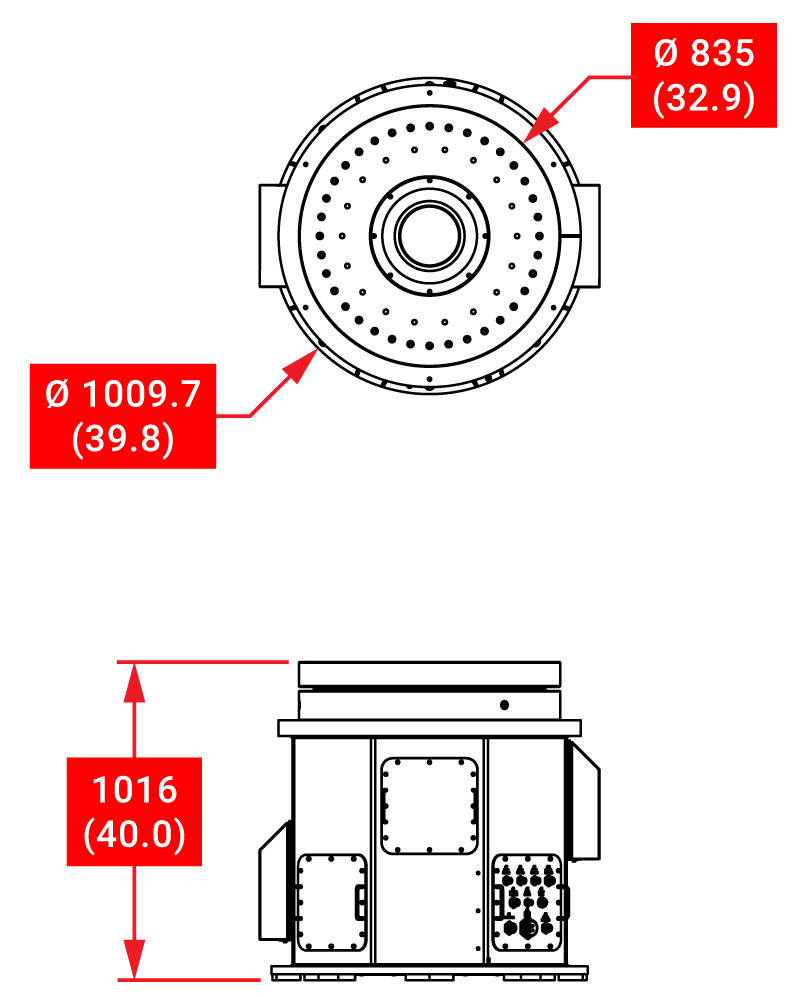

MEC-HPR-60

MEC-HPR-220

MEC-HPR-3000

-

Specifications

-

Applications

-

Includes

-

Factory Installed Options

| Parameters | Units | MEC-HPR-45 | MEC-HPR-55 | MEC-HPR-60 | MEC-HPR-220 | MEC-HPR-3000 |

|---|---|---|---|---|---|---|

| Bending Moment, Static | Nm (ft-lb) | 45,759 (33,750) |

40,675 (30,000) |

60,000 (44,254) |

223,710 (165,000) |

3,118,381 (2,300,000) |

| Bending Moment, Operation | Nm (ft-lb) | 30,506 (22,500) |

27,116 (20,000) |

40,000 (29,503) |

74,570 (55,000) |

881,282 (650,000) |

| Vertical Load | kg (lb) | 9,072 (20,000) |

4,536 (10,000) |

3,402 (7,500) |

34,019 (75,000) |

54,431 (120,000) |

| Delivered Torque (Continuous Duty) | Nm (ft-lb) | 163 (120) |

2,034 (1,500) |

758 (559) |

4,067 (3,000) |

47,454 (35,000) |

| Maximum Speed | deg/sec | 60 | 75 | 120 | 36 | 36 |

| Position Readout Accuracy (Absolute) | deg | ±0.05 (PF1) ±0.005 (PF4) |

±0.03 (PF1) ±0.005 (PF4) |

±0.05 (PF1) | ±0.02 (PF1) |

±0.02 (PF1) |

| Backlash | deg | 0.1 | 0.08 | 0.1 | Zero-Backlash | Zero-Backlash |

| Physical | ||||||

| Thru Hole Diameter1 | mm (in.) | 127 (5.0) |

108 (4.3) |

267 (10.5) |

305 (12.0) |

940 x 940 (37.0 x 37.0) |

| Turntable Diameter | mm (in.) | 610 (24.0) |

765 (30.1) |

835 (32.9) |

1,201 (47.3) |

2,318 (91.3) |

| Base Diameter | mm (in.) | 730 (28.8) |

902 (35.5) |

1,010 (39.8) |

1,422 (56.0) |

3,048 (120.0) |

| Height | mm (in.) | 368 (14.5) |

426 (16.8) |

1,016 (40.0) |

990 (39.0) |

1,509 (59.4) |

| Net Weight | kg (lb) | 318 (700) |

293 (645) |

1,089 (2,400) |

1,950 (4,300) |

11,793 (26,000) |

| Environmental | ||||||

| Operating Conditions | Direct Outdoor Exposure | |||||

| Operating Temperature Range | °C (°F) | -25 to +43 (-13 to +110) | ||||

| Storage Temperature Range | °C (°F) | -25 to +63 (-13 to +145) | ||||

| Operating Relative Humidity | % | 100 | ||||

| Storage Relative Humidity | % | 100 | ||||

| Operating Altitude | m (ft) | 2,438 (8,000) | ||||

| Storage Relative Humidity | m (ft) | 2,438 (8,000) | ||||

| Factory Installed Options | ||||||

| Position Feedback Options | PF | PF1, PF4 | PF1, PF4 | PF1 | PF1 | PF1 |

| RF Path Options | RJ | RJ26, RJ40, RJ50 | ||||

| Stow-Pin Option | SP | SP1 | ||||

| Lubrication System | ALS | ALS1 | ||||

| Riser | RS | RS1 | ||||

| Temperature control system | HT | HT1 | ||||

Ideal for

- Transportable radars

- Mobile communication

- Ground communication

- Pointing & tracking

- General purpose positioning

- Scientific and R&D

- Factory automation

- Antenna testing

Comes with:

- MEC-HPR High Power Rotator

- Instruction Manual

- Maintenance Manual

- Interface Control Drawing (ICD)

Position Feedback Option

Standard absolute feedback with encoder

PF4: High Accuracy, ±0.005 degrees native read-out accuracy for most positioners

Replaces standard absolute feedback with center-drive high accuracy absolute encoder

Notes: Options are available to further enhance the native accuracy using error correction techniques. See Enhanced Accuracy Options brochure for additional information.

RF Path Options

Adds a single channel RF path inside the rotator to support continuous, unrestricted rotation of the axis. The factory installed kit contains an RF rotary joint and internal RF cabling.

RJ26: DC-26.5 GHz, 3.5 mm | RJ40: DC-40 GHz, K | RJ50: DC-50 GHz, 2.4 mm

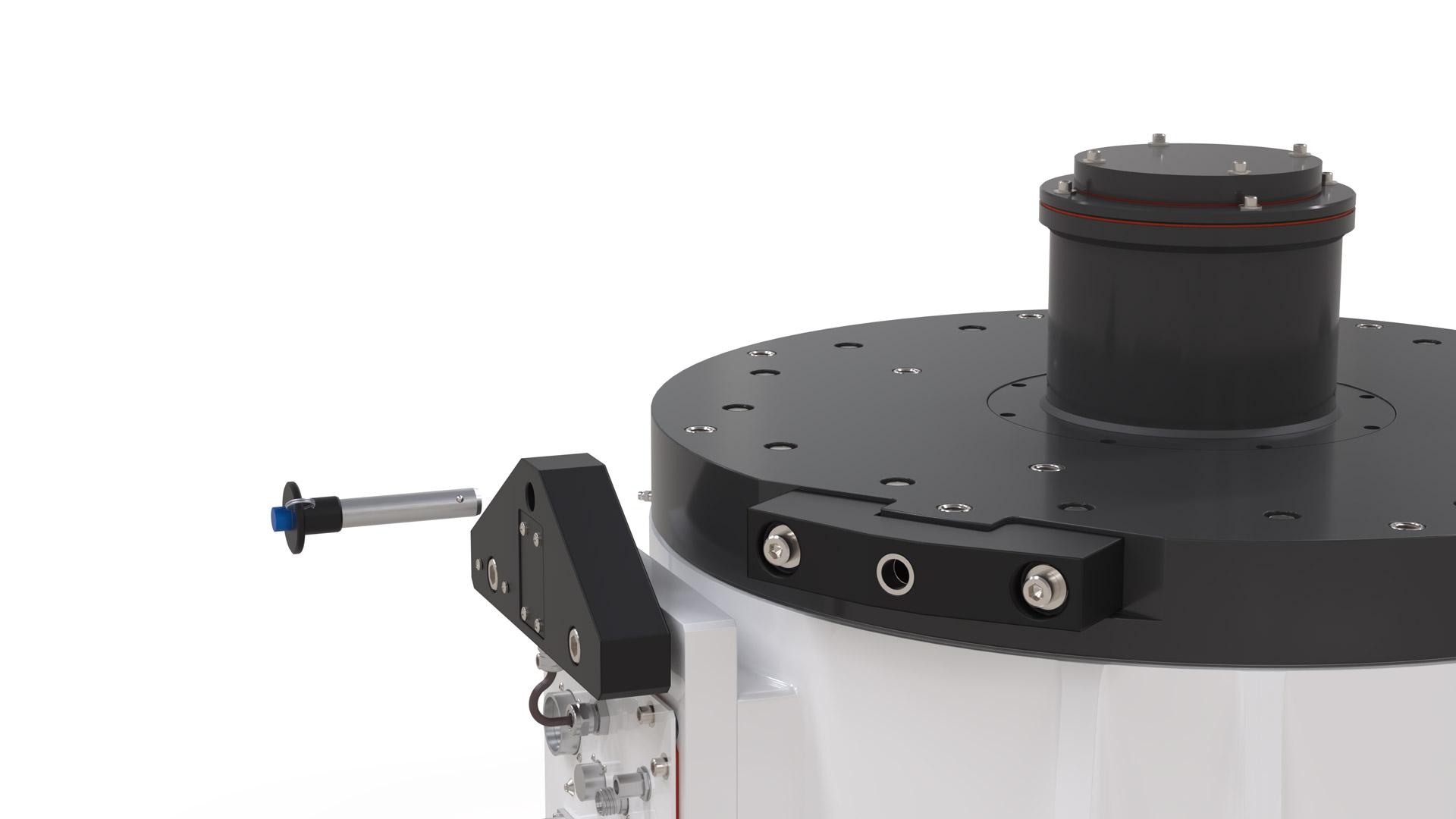

Through Path Options

Convenience & Protection Options

Adds manual stow-pin and mating receptacle to protect the positioner’s drive-train in susceptible environments such as high wind-gust exposure in outdoor environments and high-load pick-up mode applications. Includes electrical interlock circuit for disabling the servo system when stow-pin is inserted. Default position is zero (0) degrees. Alternate stow-pin angle locations are available upon request.

The automatic lubrication system is designed to inject grease into the slewing ring bearing ports and ring gear points at regular intervals ensuring continuous and maintenance-free operation.

Adds a structural riser below the positioner for applications requiring accurate centering from a platform, outdoor silo applications, and various customer requested heights. Risers are designed to withstand the full capacity of the mated positioner and are tailored to your required height. Available features include access hatches, custom color, internal shelving, and external and internal ladders.

A heater module equipped with a built-in thermostat and fan heats the internal volume of the positioner when ambient temperatures drop below freezing. Additionally, a thermostatically controlled fan evacuates warm air from the positioner if the internal temperature exceeds a programmable threshold.

.svg?la=en&revision=cee9767f-8e72-4d76-a07a-14ba25688269&hash=ADF64722447408F8CA70B4436F59CB64)